The Rise of 3D Printed Plastic Items in the COVID Pandemic

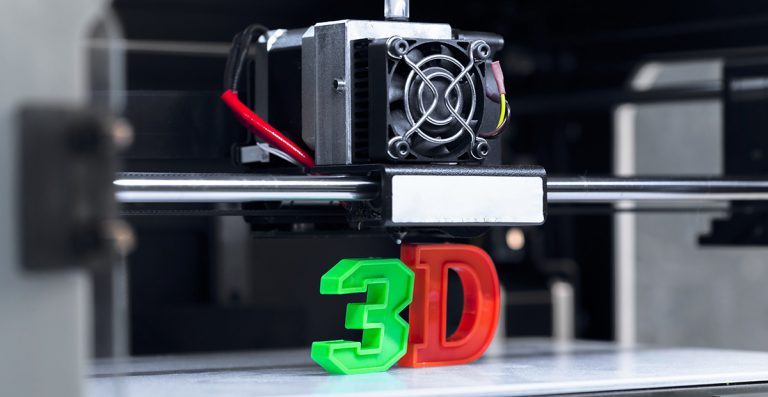

3D printing is a construction system that is computer-controlled and makes use of materials like plastic to design and create physical objects. The ease of creating objects locally, especially medical tools, can ease the burden of healthcare workers in the ongoing COVID pandemic.

The Role of Plastics in 3D Printing

3D printing technology has been around for several decades, with many organizations and researchers using photo-hardening plastics to fabricate 3D models and objects.

However, one of the most common methods of plastic 3D printing is fused filament fabrication. With this method, a filament of thermoplastic is fed into the 3D printer and is melted and applied layer-by-layer to the 3D printed object.

The Use of 3D Printing During the COVID Pandemic

Due to the ongoing pandemic, many hospitals and care centers are burdened with the demand for PPE and specific medical equipment. The global supply chain has also witnessed a disruption in the last few months, making transportation of essential equipment a challenge.

Plastic 3D printed items suffer no such disruptions. They can be created locally and could be an ideal solution to such issues.

3D printing was used to deal with the rising demand for ventilator support, and several organizations around the globe responded with 3D printed alternatives.

For instance, Plastic splitters were created with 3D printed to allow multiple patients to utilize a single ventilator. 3D printer was also used to create plastic face shields, and design well-fitting face masks. What’s more, 3D printed plastic objects can also be recycled by melting them down to their original polymer form. They can then be re-used in 3D printing.

Due to the adaptable and fast nature of 3D printing, temporary emergency shelters made from PVC fabric were also created during the pandemic. They were used in situations where hospitals were overloaded with patients and faced difficulties in isolating them. Such emergency shelters were deployed promptly, with the additional benefit of redeployment and easy transportation.

A less direct application of plastic 3D printing items that were relevant to the pandemic included the manufacture of training equipment for healthcare personnel. For instance, a company in Singapore developed 3D printed translucent training mannequins for trainees, so that they could practice collecting swabs for the COVID test.

Conclusion

As you can see, 3D printing technology was widely used in the pandemic and is here to stay. With the help of plastics, manufacturers can design and create essential items locally and in bulk. Plastic also offers many benefits of being low cost, versatile, durable, lightweight, and water-resistant, making it an ideal material for 3D printing.

Source:

https://www.news-medical.net/health/The-Rise-of-3D-Printing-in-the-COVID-19-Pandemic.aspx

Leave a Reply Cancel reply

Recent Posts

- Understanding The Materials That Are Used To Build Plastic Toys

- All You Need To Know About Food-grade Plastics

- A Glance At The Materials That Boost The Performance Of Plastics

- Understanding The Importance Of Exploring New Business Opportunities In The Plastic Industry

- Understanding The Importance Of Investing in R&D For The Plastic Industry

Categories

- 3D Printing

- AIPMA

- Automation

- Automobile Sector

- Bio Plastics

- Environment

- Innovations In Recycling

- Latest Innovations

- Molds & Dies

- News

- Packaging Industry

- Plastic

- Plastic Application

- Plastic Industry

- Plastic Market

- Plastic Myths

- Plastic News From The World

- Plastic Packaging

- Plastic Products

- Plastic Recycling

- Plastic Solar Cells

- Plastic Toys

- Plastic Waste

- Plastic World

- Plastics

- Plastics And Their Applications

- Plastics In Agriculture

- Plastics In Healthcare

- Plastics In Medical Industry

- Plasticulture

- Processing Machinery

- Recycling Machines

- Robotics

- Uncategorized

- Virtual Reality

Archives

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (3)

- May 2023 (2)

- April 2023 (2)

- March 2023 (2)

- February 2023 (2)

- January 2023 (2)

- December 2022 (3)

- November 2022 (1)

- October 2022 (1)

- September 2022 (2)

- August 2022 (1)

- July 2022 (3)

- May 2022 (3)

- March 2022 (2)

- February 2022 (1)

- January 2022 (1)

- September 2021 (2)

- August 2021 (3)

- July 2021 (4)

- June 2021 (4)

- May 2021 (3)

- April 2021 (2)

- March 2021 (4)

- November 2019 (8)

- October 2019 (8)

- September 2019 (8)

- August 2019 (8)

- July 2019 (8)

- June 2019 (8)

- May 2019 (8)

- April 2019 (8)

- March 2019 (8)

- February 2019 (11)

- January 2019 (8)

- December 2018 (8)

- November 2018 (12)

- October 2018 (12)