What makes Polyphenylsulfone an Ideal Polymer for Medical Grade Applications

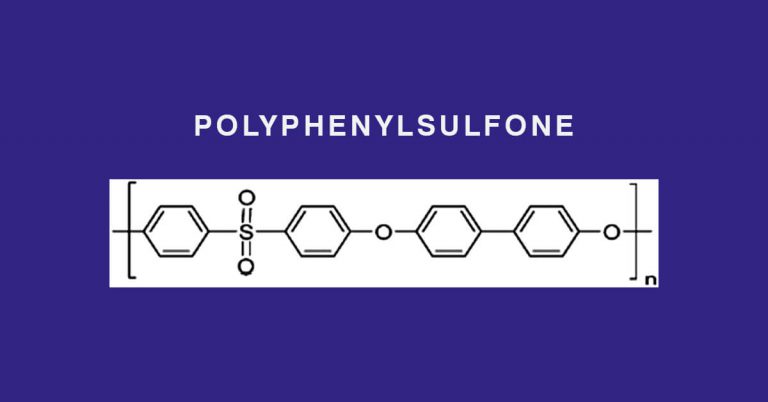

Polyphenylsulfone or PPSU has numerous properties, making it an excellent metal-replacement material for various medical applications. The most noteworthy is its heat resistance. It has the potential to withstand extreme temperatures (up to 260°C). Also, its resistance to harsh disinfectants and chemicals makes it ideal for hospitals.

Some other incredible properties are its high impact resistance, good flexural modulus, and amazing durability. All these properties make PPSU an ideal candidate for single- and multi-use surgical instruments. Its mechanical properties also make it much lighter than other types of metal medical equipment.

Let us have a better understanding of what makes PPSU a better alternative.

What makes PPSU a Better Alternative?

Well, it is clear that PPSU is better than its metal counterparts. It, however, also competes with other polymers that are used in the medical segment. One of them is Polycarbonate (PC), which is used extensively for medical applications similar to PPSU.

However, PPSU has now started to replace PC. The reason being, PPSU can offer better heat resistance, sterilization, chemical resistance, and hydrolytic stability. Due to these reasons, the longevity of the medical equipment is improved. That is a significant benefit during the current COVID-19 pandemic.

Another polymer that is known as Polyether ether ketone (PEEK) is also widely preferred in the medical industry due to its excellent resistance to detergents, chemicals, and disinfectants. It also offers good stiffness compared to PPSU. However, PPSU offers higher impact strength compared to PEEK, making it a better alternative for medical applications.

PPSU Processing Considerations

PPSU can be extruded or injection molded by using conventional equipment, and processing, accompanied by relatively high mold temperatures. PPSU can also enable secondary processing such as bonding, welding, coating, and printing.

Due to this, PPSU can be available in the form of filaments, making them suitable for complex geometric components and 3D printing for the medical sector. We can, therefore, expect huge growth in the 3D-printing sector for PPSU.

Growth Opportunities

The PPSU market is predicted to grow from 35.8 – 49.0 million pounds through 2022, with a CAGR of 6.5%. The already evolving medical sector will be a key driver for the surge in demand for PPSU.

What’s more, PPSU filaments and films are also used for assembling reusable plastic face shields. This contribution to help protect, improve, and sustain life conditions has become more evident to the medical industry. All these factors make PPSU an ideal material of choice for medical-grade applications in 2021 and beyond!

Source:

Leave a Reply Cancel reply

Recent Posts

- Understanding The Materials That Are Used To Build Plastic Toys

- All You Need To Know About Food-grade Plastics

- A Glance At The Materials That Boost The Performance Of Plastics

- Understanding The Importance Of Exploring New Business Opportunities In The Plastic Industry

- Understanding The Importance Of Investing in R&D For The Plastic Industry

Categories

- 3D Printing

- AIPMA

- Automation

- Automobile Sector

- Bio Plastics

- Environment

- Innovations In Recycling

- Latest Innovations

- Molds & Dies

- News

- Packaging Industry

- Plastic

- Plastic Application

- Plastic Industry

- Plastic Market

- Plastic Myths

- Plastic News From The World

- Plastic Packaging

- Plastic Products

- Plastic Recycling

- Plastic Solar Cells

- Plastic Toys

- Plastic Waste

- Plastic World

- Plastics

- Plastics And Their Applications

- Plastics In Agriculture

- Plastics In Healthcare

- Plastics In Medical Industry

- Plasticulture

- Processing Machinery

- Recycling Machines

- Robotics

- Uncategorized

- Virtual Reality

Archives

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (3)

- May 2023 (2)

- April 2023 (2)

- March 2023 (2)

- February 2023 (2)

- January 2023 (2)

- December 2022 (3)

- November 2022 (1)

- October 2022 (1)

- September 2022 (2)

- August 2022 (1)

- July 2022 (3)

- May 2022 (3)

- March 2022 (2)

- February 2022 (1)

- January 2022 (1)

- September 2021 (2)

- August 2021 (3)

- July 2021 (4)

- June 2021 (4)

- May 2021 (3)

- April 2021 (2)

- March 2021 (4)

- November 2019 (8)

- October 2019 (8)

- September 2019 (8)

- August 2019 (8)

- July 2019 (8)

- June 2019 (8)

- May 2019 (8)

- April 2019 (8)

- March 2019 (8)

- February 2019 (11)

- January 2019 (8)

- December 2018 (8)

- November 2018 (12)

- October 2018 (12)