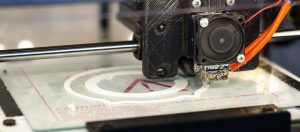

5 Incredible Benefits that Plastic 3D Printing Offer

3D printing creates parts by building up objects one layer at a time. It is able to deliver a design quickly with high accuracy to create an optimal product. Its applications are unlimited and are used in the plastic, packaging, healthcare and, the automotive industry. 3D printing is done with different types of 3D materials like PEBA plastic, stainless steel, and polyjet resins. In this blog, let’s focus on the five benefits of plastic 3D printing.

1)More Affordable

Traditional ways of injection mold tools are expensive compared to plastic 3D printing which offers affordable options to create parts and tools. For example, in the medical industry, 3D printing surgical tools like clamps, forceps, scalpel handles, and 3D printing prosthetics are low-cost compared to the traditional ones. Even the customization becomes easy, saving a lot of time and money.

2)Faster Output

3D printing only takes hours in which the design engineer only needs a 3D file that can be uploaded to a 3D printing service and does not require producing molds for prototyping. For alterations, the designer has to work on the 3D model using 3D software and then print it. This results in reduced cycle time, quicker turnarounds and faster productivity.

3)Easy Customization

Industries use mass production to cut costs and save time. This means similar products with zero uniqueness. But 3D printing offers the manufacturers the option to personalize anything without additional cost burden. Medical and dental products are tailored to the individual via 3D printing.

4)More Efficient

3D printed plastic is a great asset for various industries, especially in plastic manufacturing. Manufacturing plastic parts using 3D printing technology proves to be very easy compared to techniques like plastic injection molding

5)Mitigates Risk

With plastic 3D printing, designers are able to verify a design by printing a production-ready prototype followed by manufacturing equipment like the molds or tools. This eliminates risk during the prototyping process, saving a lot of time and money. It builds confidence before making large investments that are required for mass production.

As we see, 3D plastic printing is proving to be a great asset for various industries. Plastics can be extremely useful in every step of the product development process and can even print complex designs with ease. 3D printing or additive manufacturing is rapidly expanding the future demand for plastic materials. To meet this ever-growing demand for rapid prototyping and manufacturing, more and more high-quality plastics will be modified for 3D printing.

If you are in the 3D printing industry then Plastivision is a great platform for you to showcase your product range and network with industry professionals. Book your booth today!

Leave a Reply Cancel reply

Recent Posts

- Understanding The Materials That Are Used To Build Plastic Toys

- All You Need To Know About Food-grade Plastics

- A Glance At The Materials That Boost The Performance Of Plastics

- Understanding The Importance Of Exploring New Business Opportunities In The Plastic Industry

- Understanding The Importance Of Investing in R&D For The Plastic Industry

Categories

- 3D Printing

- AIPMA

- Automation

- Automobile Sector

- Bio Plastics

- Environment

- Innovations In Recycling

- Latest Innovations

- Molds & Dies

- News

- Packaging Industry

- Plastic

- Plastic Application

- Plastic Industry

- Plastic Market

- Plastic Myths

- Plastic News From The World

- Plastic Packaging

- Plastic Products

- Plastic Recycling

- Plastic Solar Cells

- Plastic Toys

- Plastic Waste

- Plastic World

- Plastics

- Plastics And Their Applications

- Plastics In Agriculture

- Plastics In Healthcare

- Plastics In Medical Industry

- Plasticulture

- Processing Machinery

- Recycling Machines

- Robotics

- Uncategorized

- Virtual Reality

Archives

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (3)

- May 2023 (2)

- April 2023 (2)

- March 2023 (2)

- February 2023 (2)

- January 2023 (2)

- December 2022 (3)

- November 2022 (1)

- October 2022 (1)

- September 2022 (2)

- August 2022 (1)

- July 2022 (3)

- May 2022 (3)

- March 2022 (2)

- February 2022 (1)

- January 2022 (1)

- September 2021 (2)

- August 2021 (3)

- July 2021 (4)

- June 2021 (4)

- May 2021 (3)

- April 2021 (2)

- March 2021 (4)

- November 2019 (8)

- October 2019 (8)

- September 2019 (8)

- August 2019 (8)

- July 2019 (8)

- June 2019 (8)

- May 2019 (8)

- April 2019 (8)

- March 2019 (8)

- February 2019 (11)

- January 2019 (8)

- December 2018 (8)

- November 2018 (12)

- October 2018 (12)