Robotic Automation – The Future of Plastic Manufacturing

With complete automation in the entire process chain from part insertion to packaging and labeling, the plastic industry is poised to handle the most demanding tasks. It has developed into one of the most important markets for all robot manufacturers in recent years.

Automation can be a big investment, hence marketplaces want to ensure that they understand the potential benefits of robotics, its profit earnings, and its efficiency. The general notion of automation is posing a threat to manpower that overshadows its potential benefits. Let us look at some incredible advantages that robotic automation have to offer:

(Link: https://www.facebook.com/Plastivision/videos/2319946014905673/)

1) Precision

Robotic processes work with high precision which enables manufacturers to provide the highest quality product.

2) Efficiency

Robots can work 24/7 with little or no supervision and gain huge output. Thus, companies can reallocate their manpower services to other functioning areas to maximize their skills.

3) Speed

The speed of robots cannot be matched with manual labor. This helps reduce production time and gain impressive results.

4) Flexibility

Articulated robots provide the ability to mount in several orientations and can rotate freely in multiple orientations.

5) Integrated system

Built with intelligent design, robots require minimal maintenance. They can be installed in minimal spaces and are highly compact and flexible.

6) Safety

Robots perform repetitive and potentially dangerous tasks without much effort. This reduces the likelihood of accidental or other health hazards that come with labor services.

7) Cost

They provide error-free work and require no extensive training or in-depth specialist knowledge. This helps companies recover the cost with a quick ROI. Companies achieve more production with minimal mistakes than a human resource.

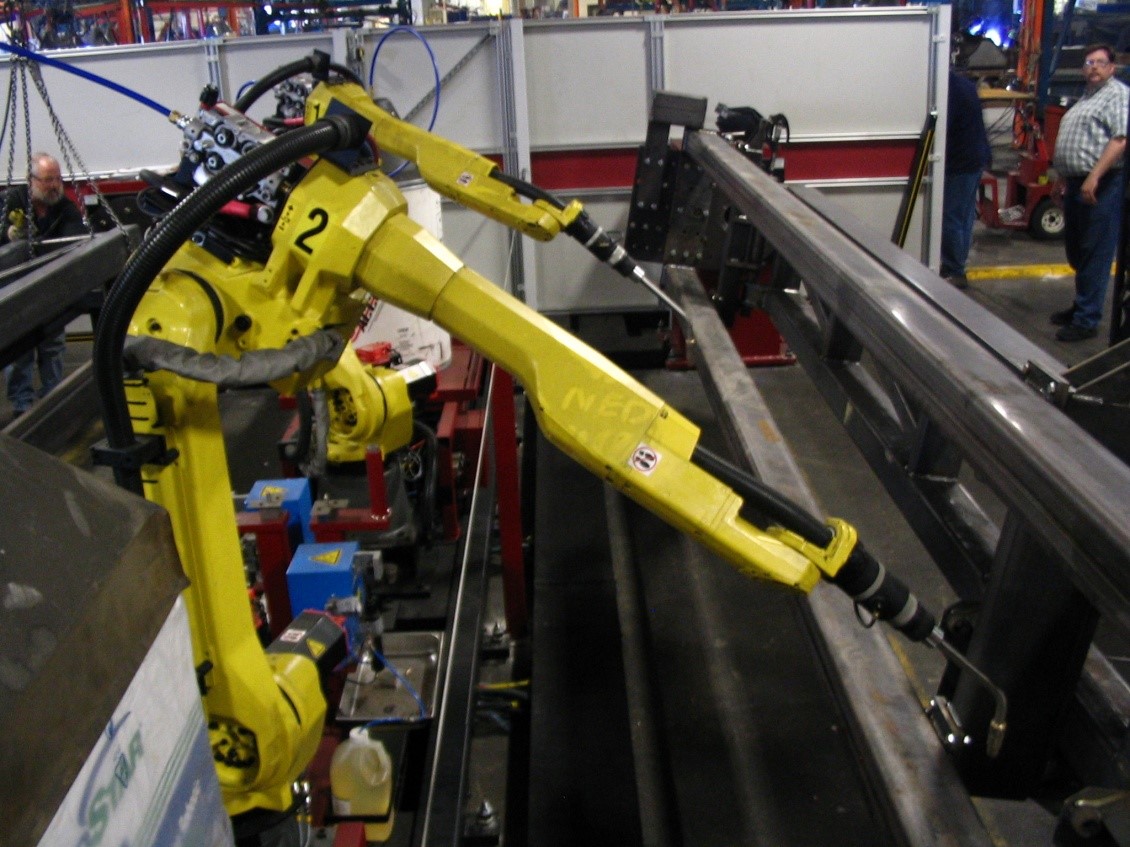

Welding Robots – A type of Industrial Robot

What Role Does Robots Play in Plastics Manufacturing?

To compete on a global scale and expand into new markets, it is imperative for plastic manufacturers to automate production. To increase production, manufacturers are using easily integrated production monitoring software to provide real-time access to equipment status. From simple collaborative robots to complex automated tooling, the industry is taking full advantage of new technologies in automation.

Plastic injection molding which includes automation is becoming the most preferred choice for part manufacturers because of its higher volume production and increasing revenue and profit margins.

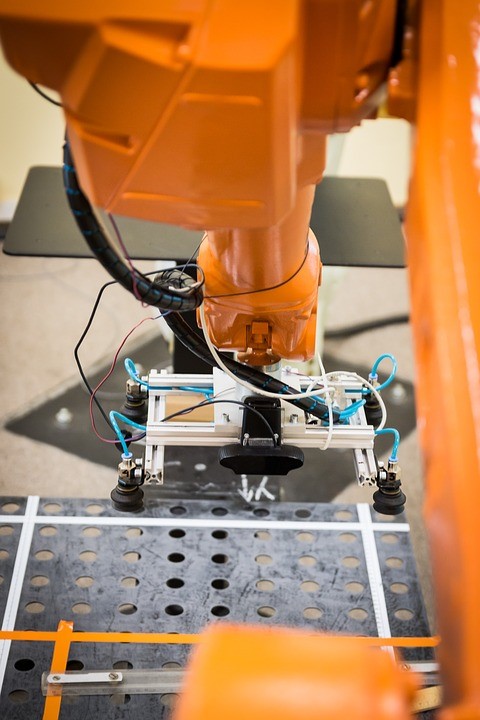

Robotic Arm

Benefits of Implementing Robotics in Plastic Industry

With the implementation of robotics and automation, the plastic industry has achieved a competitive edge in the overseas manufacturing market. Integration of robotics in plastic injection molding has provided many advantages such as consistency, high-quality, enhanced features, speed and a consistent production cycle time that has reduced labor costs.

Robotics has been successfully implemented in many areas of plastic manufacturing, which includes:

- Part insertion/extraction

- Degating / Trimming / Cutting

- Secondary part operations such as insertion of clips, gate cutting, loading of inserts, quality control checks

- Post-secondary operations such as assembly, part making, inspection, packing, palletizing

The incredible benefits that robotics offer has given it a competitive edge in today’s changing market. What’s more, they are here to stay and will continue to offer long term benefits to plastic manufacturing companies and their customers.

Wish to know more about robotic automation and how it can benefit your business? Then be a part of Plastivision trade show.

Leave a Reply Cancel reply

Recent Posts

- Understanding The Materials That Are Used To Build Plastic Toys

- All You Need To Know About Food-grade Plastics

- A Glance At The Materials That Boost The Performance Of Plastics

- Understanding The Importance Of Exploring New Business Opportunities In The Plastic Industry

- Understanding The Importance Of Investing in R&D For The Plastic Industry

Categories

- 3D Printing

- AIPMA

- Automation

- Automobile Sector

- Bio Plastics

- Environment

- Innovations In Recycling

- Latest Innovations

- Molds & Dies

- News

- Packaging Industry

- Plastic

- Plastic Application

- Plastic Industry

- Plastic Market

- Plastic Myths

- Plastic News From The World

- Plastic Packaging

- Plastic Products

- Plastic Recycling

- Plastic Solar Cells

- Plastic Toys

- Plastic Waste

- Plastic World

- Plastics

- Plastics And Their Applications

- Plastics In Agriculture

- Plastics In Healthcare

- Plastics In Medical Industry

- Plasticulture

- Processing Machinery

- Recycling Machines

- Robotics

- Uncategorized

- Virtual Reality

Archives

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (3)

- May 2023 (2)

- April 2023 (2)

- March 2023 (2)

- February 2023 (2)

- January 2023 (2)

- December 2022 (3)

- November 2022 (1)

- October 2022 (1)

- September 2022 (2)

- August 2022 (1)

- July 2022 (3)

- May 2022 (3)

- March 2022 (2)

- February 2022 (1)

- January 2022 (1)

- September 2021 (2)

- August 2021 (3)

- July 2021 (4)

- June 2021 (4)

- May 2021 (3)

- April 2021 (2)

- March 2021 (4)

- November 2019 (8)

- October 2019 (8)

- September 2019 (8)

- August 2019 (8)

- July 2019 (8)

- June 2019 (8)

- May 2019 (8)

- April 2019 (8)

- March 2019 (8)

- February 2019 (11)

- January 2019 (8)

- December 2018 (8)

- November 2018 (12)

- October 2018 (12)