The Role of Plastic at Tesla’s Gigafactory

In the quest to mass produce affordable electric cars, billionaire Entrepreneur Elon Musk has invested $5 billion to build a Gigafactory in Nevada, USA. The factory is designed to manufacture batteries that are the heart of the electric vehicles. In order to make his vision a reality, plastics were used extensively throughout the factory in machines, batteries, and solar panels. Let us look at the role that these plastics have played at Tesla’s Gigafactory.

Lithium Battery Separators

The main purpose for the inception of Gigafactory and a vital part of Tesla’s electric vehicles is Lithium battery. The company produces complete production cells including separators. As per Plastic News, separators are a part of all modern lithium batteries and are made from pieces of thermoplastic film. Even thou these thin films of sheers are out of sight and small they help to separate the anode and the cathode. This ensures that the batteries function smoothly and efficiently.

Green Energy

The Gigafactory is utilizing renewable green energy that is generated from solar panels on the factory’s roof. The solar panels are constructed using solar polymer cells which are created using plastic. The turbines that generate electricity from solar energy are also made out of plastic. It is safe to say that plastic is playing a vital role in powering the factory.

AIV (Autonomous Indoor Vehicle)

The Gigafactory has multiple fascinating elements, one of them is the high use of automation and autonomous indoor vehicles. These AIV’s can easily move raw materials and finished good inventories in the factory and are designed to be self-navigating. These vehicles come in different shapes, sizes and have different functionalities. This is made possible because many of them are made with advanced level plastics.

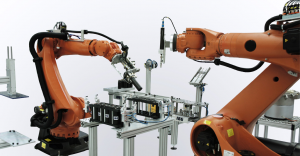

Battery Assembly Robots

Plastics have been playing a huge role in the functionality and the built of these robots. Whether plastic casings for computer hardware, plastic tubings for multiple operating fluids, plastic have a major role when it comes to the battery assembly process in the factory. The robots that assemble the lithium batteries make use of plastic and computer technology extensively.

It is clear that highly complex plastics are playing a huge role in the rapid development of electric vehicles in the Gigafactory and will continue to push the envelope of innovation in the coming years. If you are in the plastic industry, then Plastivision is a great platform for you to showcase your product range and network with industry professionals. Book your booth today!

Leave a Reply Cancel reply

Recent Posts

- Understanding The Materials That Are Used To Build Plastic Toys

- All You Need To Know About Food-grade Plastics

- A Glance At The Materials That Boost The Performance Of Plastics

- Understanding The Importance Of Exploring New Business Opportunities In The Plastic Industry

- Understanding The Importance Of Investing in R&D For The Plastic Industry

Categories

- 3D Printing

- AIPMA

- Automation

- Automobile Sector

- Bio Plastics

- Environment

- Innovations In Recycling

- Latest Innovations

- Molds & Dies

- News

- Packaging Industry

- Plastic

- Plastic Application

- Plastic Industry

- Plastic Market

- Plastic Myths

- Plastic News From The World

- Plastic Packaging

- Plastic Products

- Plastic Recycling

- Plastic Solar Cells

- Plastic Toys

- Plastic Waste

- Plastic World

- Plastics

- Plastics And Their Applications

- Plastics In Agriculture

- Plastics In Healthcare

- Plastics In Medical Industry

- Plasticulture

- Processing Machinery

- Recycling Machines

- Robotics

- Uncategorized

- Virtual Reality

Archives

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (3)

- May 2023 (2)

- April 2023 (2)

- March 2023 (2)

- February 2023 (2)

- January 2023 (2)

- December 2022 (3)

- November 2022 (1)

- October 2022 (1)

- September 2022 (2)

- August 2022 (1)

- July 2022 (3)

- May 2022 (3)

- March 2022 (2)

- February 2022 (1)

- January 2022 (1)

- September 2021 (2)

- August 2021 (3)

- July 2021 (4)

- June 2021 (4)

- May 2021 (3)

- April 2021 (2)

- March 2021 (4)

- November 2019 (8)

- October 2019 (8)

- September 2019 (8)

- August 2019 (8)

- July 2019 (8)

- June 2019 (8)

- May 2019 (8)

- April 2019 (8)

- March 2019 (8)

- February 2019 (11)

- January 2019 (8)

- December 2018 (8)

- November 2018 (12)

- October 2018 (12)