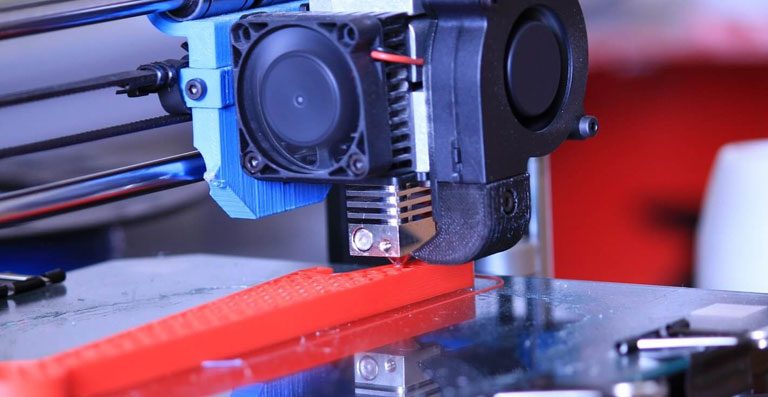

Why HDPE is the Preferred Material of Choice for 3D Printing

HDPE which stands for high-density polyethylene is a thermoplastic polymer. It is made from the monomer ethylene and is ubiquitous for its great strength-to-density ratio. It is extremely strong yet light enough to float. Its molecular branch is the reason behind its intermolecular force and tensile strength. HDPE is designed for an optimum balance of density and can withstand high temperatures. With the rapid HDPE is fast gaining popularity as a 3D printing material. Let us look at why it is the ideal material for 3D printing:

1. Watertight:

HDPE makes for a great material to manufacture containers and is widely popular in the production of liquid containers. The reason being it is not soluble in water. This characteristic makes it preferable to create 3D printed containers.

2. Lightweight:

One of the major reasons why HDPE is considered as one of the best materials for 3D printing is due to its lightweight and enhanced strength property. The high strength of HDPE is relative to its mass. The reason being, the composition of HDPE keeps it from splitting at a molecular level. Therefore, when it comes to 3D printing, HDPE provides excellent support for extensive designs that are lightweight.

3. Dissolvable:

What makes HDPE an ideal material for 3D printing is its ability to be dissolvable in limonene which is an organic chemical. For designs that require gaps between sections or overhanging details, a temporary scaffolding can be printed using HDPE to hold those sections as they are printing. Once the product is designed, it can be dunked in limonene. The HDPE will dissolve and will leave your design in perfect shape.

4. FDA Approved:

HDPE is non-toxic and has been given a food safe rating by the FDA. This means you can eat off it without any repercussions to your health. This is great when it comes to printing 3D medical objects without worrying about the end product being contaminated by biological material.

5. Recyclable:

One of the most commonly recycled plastics in the world, HDPE carries a universal sign for recycling. It has a “Number 2” inside the recycling triangle to indicate that it is recyclable. HDPE’s incredible benefit is that it can be easily recycled. Converting it into 3D printing filaments offers a massive advantage when it comes to using making efficient use of plastic waste. Any kind of unused or finished objects that you are not being used, can be turned into 3D printing filaments. These products can include plumbing pipes that help people get clean water, consumer goods containers and children’s toys.

If you are in 3D printing business then come visit Plastivision. It is an incredible platform to discover incredible plastic products that will help boost your business.

Leave a Reply Cancel reply

Recent Posts

- Understanding The Materials That Are Used To Build Plastic Toys

- All You Need To Know About Food-grade Plastics

- A Glance At The Materials That Boost The Performance Of Plastics

- Understanding The Importance Of Exploring New Business Opportunities In The Plastic Industry

- Understanding The Importance Of Investing in R&D For The Plastic Industry

Categories

- 3D Printing

- AIPMA

- Automation

- Automobile Sector

- Bio Plastics

- Environment

- Innovations In Recycling

- Latest Innovations

- Molds & Dies

- News

- Packaging Industry

- Plastic

- Plastic Application

- Plastic Industry

- Plastic Market

- Plastic Myths

- Plastic News From The World

- Plastic Packaging

- Plastic Products

- Plastic Recycling

- Plastic Solar Cells

- Plastic Toys

- Plastic Waste

- Plastic World

- Plastics

- Plastics And Their Applications

- Plastics In Agriculture

- Plastics In Healthcare

- Plastics In Medical Industry

- Plasticulture

- Processing Machinery

- Recycling Machines

- Robotics

- Uncategorized

- Virtual Reality

Archives

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (3)

- May 2023 (2)

- April 2023 (2)

- March 2023 (2)

- February 2023 (2)

- January 2023 (2)

- December 2022 (3)

- November 2022 (1)

- October 2022 (1)

- September 2022 (2)

- August 2022 (1)

- July 2022 (3)

- May 2022 (3)

- March 2022 (2)

- February 2022 (1)

- January 2022 (1)

- September 2021 (2)

- August 2021 (3)

- July 2021 (4)

- June 2021 (4)

- May 2021 (3)

- April 2021 (2)

- March 2021 (4)

- November 2019 (8)

- October 2019 (8)

- September 2019 (8)

- August 2019 (8)

- July 2019 (8)

- June 2019 (8)

- May 2019 (8)

- April 2019 (8)

- March 2019 (8)

- February 2019 (11)

- January 2019 (8)

- December 2018 (8)

- November 2018 (12)

- October 2018 (12)