3D Printed Diamond Composite Innovation Opens New Path for Industries

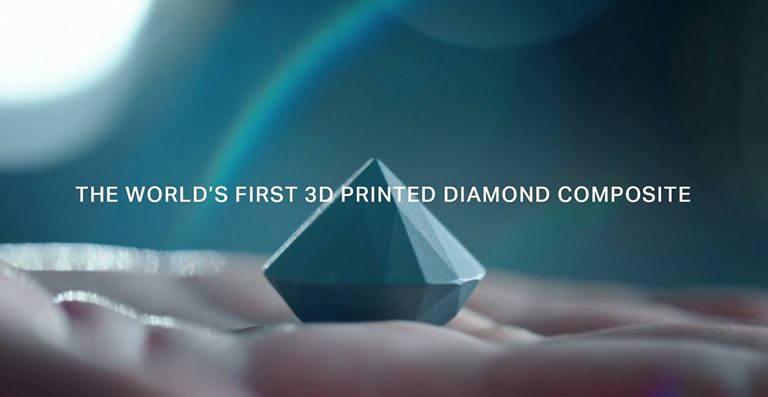

An additive manufacturing and printing company known as Sandvik has found a revolutionary way to use the hardest natural material on the planet- diamond. This manufacturing company has created the first-ever 3D printed diamond composite. While this 3D printed diamond composite does not sparkle, it is perfect for a wide range of industrial uses. This super-hard material can now be printed in 3D in highly complex shapes.

Diamond is a material that is harder than anything else in nature. It is one of the key components when it comes to a wide range of wear-resistant tools in the industry such as mining and drilling to machining and medical implants. A diamond by its nature is hard, complicated to machine and close to impossible to form complex shapes. It became possible to produce a synthetic diamond in 1953. But since it’s so hard and complicated to machine, it makes it almost impossible to form complex shapes.

Utilizing additive manufacturing, Sandvik has managed to 3D-print diamond composites that can be formed in almost any shape. This big breakthrough has opened up the possibility of using it in applications that were previously considered impossible.

With the ability to create strong diamond composites in very complex shapes through additive manufacturing, the only limit to how this super-hard material can be shaped and used is down to the designer’s imagination. This development will fundamentally change the way industries will be able to use this material.

The distinction between Sandvik’s diamond and natural or synthetic diamond is that Sandvik’s is a composite material. The majority of the material is diamond, but to make it printable and dense it needs to be cemented in a very hard matrix material, therefore, retaining the most important physical properties of pure diamond.

Sandvik’s 3D printed diamond composite has opened new pathways for industries that rely on diamonds for industrial, manufacturing, and design work. Industries can now use diamond in applications and shapes never conceived possible before. This innovation will allow industries to print anything, in any shape – in diamond.

On testing, this diamond composite has been found to have extremely high hardness, exceptional heat conductivity, at the same time possessing low density, very good thermal expansion, and fantastic corrosion resistance. This 3D printed diamond composite has certainly paved the way for limitless possibilities for various industries.

Leave a Reply Cancel reply

Recent Posts

- Understanding The Materials That Are Used To Build Plastic Toys

- All You Need To Know About Food-grade Plastics

- A Glance At The Materials That Boost The Performance Of Plastics

- Understanding The Importance Of Exploring New Business Opportunities In The Plastic Industry

- Understanding The Importance Of Investing in R&D For The Plastic Industry

Categories

- 3D Printing

- AIPMA

- Automation

- Automobile Sector

- Bio Plastics

- Environment

- Innovations In Recycling

- Latest Innovations

- Molds & Dies

- News

- Packaging Industry

- Plastic

- Plastic Application

- Plastic Industry

- Plastic Market

- Plastic Myths

- Plastic News From The World

- Plastic Packaging

- Plastic Products

- Plastic Recycling

- Plastic Solar Cells

- Plastic Toys

- Plastic Waste

- Plastic World

- Plastics

- Plastics And Their Applications

- Plastics In Agriculture

- Plastics In Healthcare

- Plastics In Medical Industry

- Plasticulture

- Processing Machinery

- Recycling Machines

- Robotics

- Uncategorized

- Virtual Reality

Archives

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (3)

- May 2023 (2)

- April 2023 (2)

- March 2023 (2)

- February 2023 (2)

- January 2023 (2)

- December 2022 (3)

- November 2022 (1)

- October 2022 (1)

- September 2022 (2)

- August 2022 (1)

- July 2022 (3)

- May 2022 (3)

- March 2022 (2)

- February 2022 (1)

- January 2022 (1)

- September 2021 (2)

- August 2021 (3)

- July 2021 (4)

- June 2021 (4)

- May 2021 (3)

- April 2021 (2)

- March 2021 (4)

- November 2019 (8)

- October 2019 (8)

- September 2019 (8)

- August 2019 (8)

- July 2019 (8)

- June 2019 (8)

- May 2019 (8)

- April 2019 (8)

- March 2019 (8)

- February 2019 (11)

- January 2019 (8)

- December 2018 (8)

- November 2018 (12)

- October 2018 (12)