Researchers Design Ultra-Thin Plastic Films that are Thermally Conductive

The go-to material for thermal insulation has usually been plastics. For instance, polymer-based materials such as a Styrofoam coffee cup or silicone oven mitts are great at trapping heat. However, the image of polymers as insulators has now been flipped. A team of researchers from the Massachusetts Institute of Technology (MIT) has designed thin plastic films that are capable of conducting heat. These plastic films are thinner than plastic wraps and can conduct heat better than metals and ceramics.

The team’s research is likely to prompt the production of flexible, corrosion-resistant, and lightweight plastic insulators that could replace traditional metal heat conductors. The applications could range from cooling materials in refrigerators and cars to heat-dissipating elements in smart-phones and laptops. According to Professor Gang Chen at MIT, thermally conductive plastics hold the power to design new applications, industries and could replace metals or alloys as heat exchangers.

The team’s research is likely to prompt the production of flexible, corrosion-resistant, and lightweight plastic insulators that could replace traditional metal heat conductors. The applications could range from cooling materials in refrigerators and cars to heat-dissipating elements in smart-phones and laptops. According to Professor Gang Chen at MIT, thermally conductive plastics hold the power to design new applications, industries and could replace metals or alloys as heat exchangers.

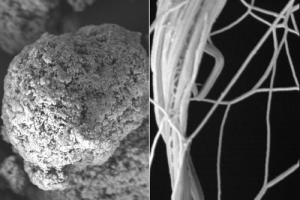

To create the plastic film, the researchers untangled polyethylene’s molecular knots. Out of these knots, parallel chains that conducted heat were formed. They then designed a custom-built flow system that further untangled the molecular chain. The solution was then transferred onto a liquid-nitrogen-cooled plate and a thick film was formed. The film was then heated and stretched to make it thinner than plastic wrap.

An apparatus was designed by the team to measure the heat conduction of the film. Most polymers conduct heat at around 0.1 to 0.5 W/m⋅K whereas the polyethylene film measured at an astonishing 60 W/m⋅K. What’s more, it turns out that the new film is more conductive than ceramic and steel. Ceramic measures about 30 W/m⋅K and steel measures around 15 W/m⋅K.

After imaging the ultra-thin films, it was observed that the material exhibited properties that were consistent with nanofibres. This could further help researchers to create polymer microstructures that efficiently conducted heat. The team is now working to enhance polymer heat conductors by experimenting with various types of materials and tweaking the fabrication process. It won’t come as a surprise if we start seeing this material being used in electronic devices, printed circuit boards casings for batteries and heat conductors in automobiles.

If you are in the plastic industry, then Plastivision is a great platform for you to showcase your product range and network with industry professionals. Book your booth today!

Leave a Reply Cancel reply

Recent Posts

- Understanding The Materials That Are Used To Build Plastic Toys

- All You Need To Know About Food-grade Plastics

- A Glance At The Materials That Boost The Performance Of Plastics

- Understanding The Importance Of Exploring New Business Opportunities In The Plastic Industry

- Understanding The Importance Of Investing in R&D For The Plastic Industry

Categories

- 3D Printing

- AIPMA

- Automation

- Automobile Sector

- Bio Plastics

- Environment

- Innovations In Recycling

- Latest Innovations

- Molds & Dies

- News

- Packaging Industry

- Plastic

- Plastic Application

- Plastic Industry

- Plastic Market

- Plastic Myths

- Plastic News From The World

- Plastic Packaging

- Plastic Products

- Plastic Recycling

- Plastic Solar Cells

- Plastic Toys

- Plastic Waste

- Plastic World

- Plastics

- Plastics And Their Applications

- Plastics In Agriculture

- Plastics In Healthcare

- Plastics In Medical Industry

- Plasticulture

- Processing Machinery

- Recycling Machines

- Robotics

- Uncategorized

- Virtual Reality

Archives

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (3)

- May 2023 (2)

- April 2023 (2)

- March 2023 (2)

- February 2023 (2)

- January 2023 (2)

- December 2022 (3)

- November 2022 (1)

- October 2022 (1)

- September 2022 (2)

- August 2022 (1)

- July 2022 (3)

- May 2022 (3)

- March 2022 (2)

- February 2022 (1)

- January 2022 (1)

- September 2021 (2)

- August 2021 (3)

- July 2021 (4)

- June 2021 (4)

- May 2021 (3)

- April 2021 (2)

- March 2021 (4)

- November 2019 (8)

- October 2019 (8)

- September 2019 (8)

- August 2019 (8)

- July 2019 (8)

- June 2019 (8)

- May 2019 (8)

- April 2019 (8)

- March 2019 (8)

- February 2019 (11)

- January 2019 (8)

- December 2018 (8)

- November 2018 (12)

- October 2018 (12)